Hotline:+86 17712582558

Email: sales@xhextrusion.com

Website: www.xhextrusion.com

Add: Huangqiao Industrial Park, Taixing City, Taizhou City, Jiangsu Province

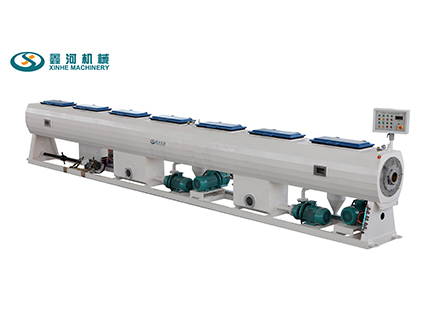

This production line is suitable for the production of PVC plastic reinforcement spiral reinforced hose (also known as plastic reinforcement spiral pipe), its degree of automation and production technology to reach the highest level

| Model | HDS45 | HDS65 |

| Extruder | SJ45/28 | SJ65/28 |

| Dlameter Range(mm) | Φ13-Φ50 | Φ64-Φ200 |

Out Put(kg/h) | 20-40 | 40-75 |

| Installed Power(kw) | 35 | 50 |

This production line is suitable for the production of PVC plastic reinforcement spiral reinforced hose (also known as plastic reinforcement spiral pipe), its degree of automation and production technology to reach the highest level. The PVC plastic reinforcement spiral pipe produced has the characteristics of extrusion resistance, corrosion resistance, negative pressure resistance, bending resistance, good fluidity and so on, suitable for gas, liquid and powder and granular conveying mainly used in industry, agriculture, construction and irrigation and other fields.

The working process of PVC Spiral Hose Production Line :

Raw material → extruder → vacuum table → haul-off → cutting machine → stacker

Twin screw extruderElectric control cabinet: inverter and feeding frequency converter Motor: main motor 75KW,feeder motor 1.5KW Capacity:300-400kg/h Extrusion speed control method:Frequency conversion speed Major electrical components: Schneider |  |

| Vacuum table machineLength: 4-6Meters Table fore-and-aft Move: Adopt 1.5KW Gearbox Speed Reducer Motor Moving left and right range and material:50mm / handwork Moving up and down range and material:800mm / handwork |

Haul-offBracket Compaction Mode: Adopt pneumatic gas cylinder Cut Motor Power: 0.75KW*1PC Impact method:Penumatic impact |

| CutterCutting action controller : PLC The impact method:pneumatic impact Cutter structure:Saw type Saw rotation speed:Pneumatic |