Hotline:+86 17712582558

Email: sales@xhextrusion.com

Website: www.xhextrusion.com

Add: Huangqiao Industrial Park, Taixing City, Taizhou City, Jiangsu Province

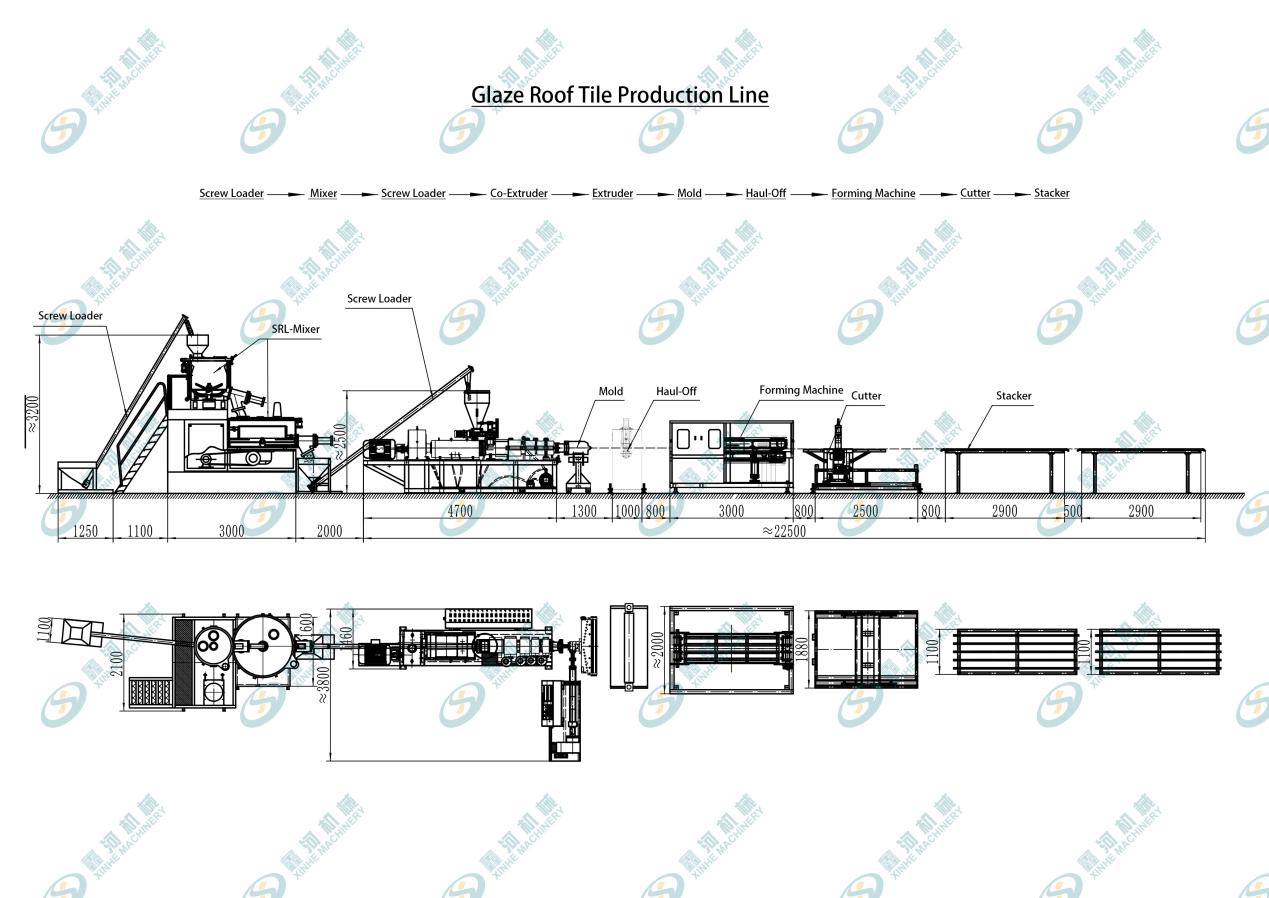

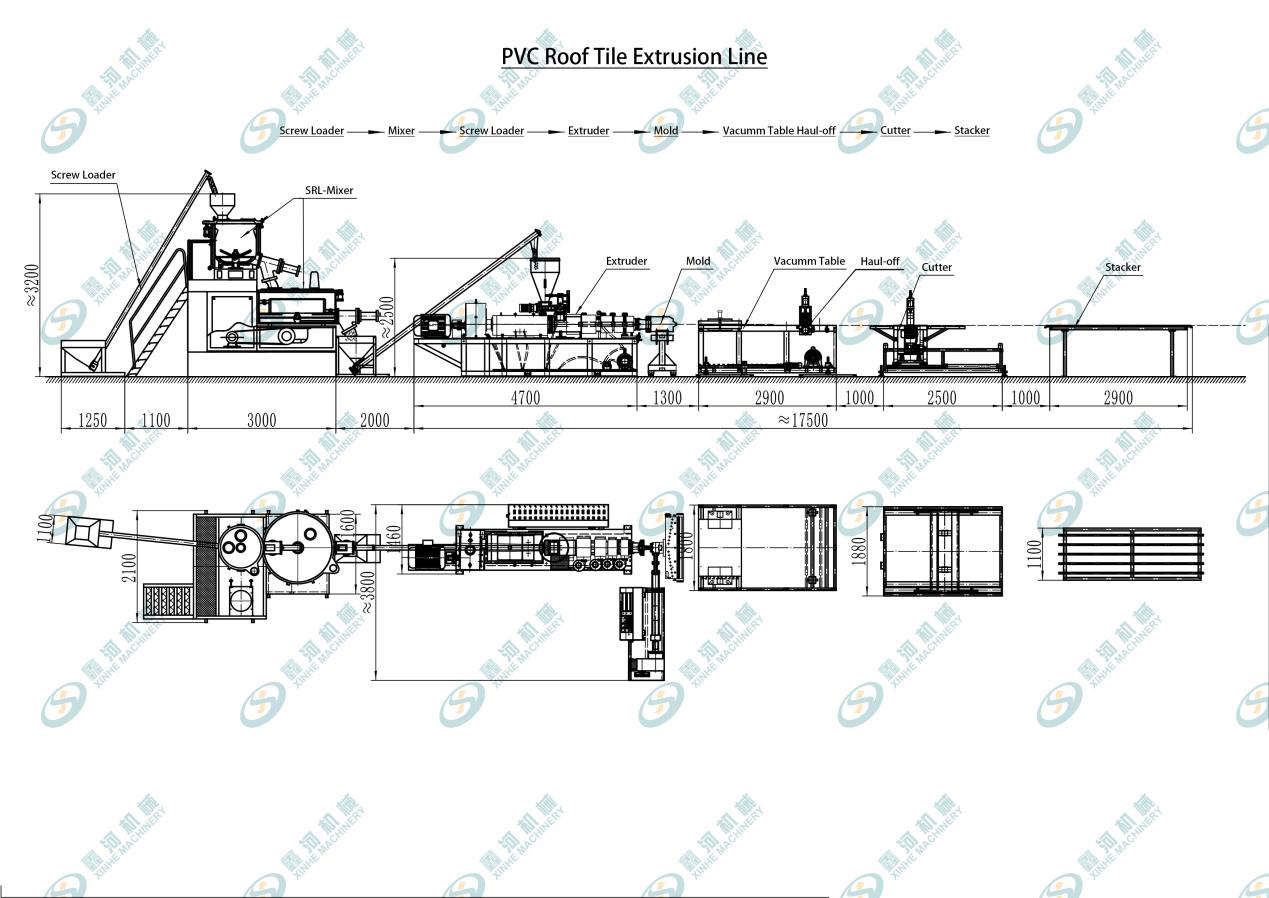

The production line is mainly composed of feeding machine, twin screw extruder, mold, forming machine (glazed tile)/setting mold (wave tile), haul-off, cutting machine and stacking rack.After the material is plasticized by the extruder, it is extruded into sheets by the mold, and made into the shape

| Layer structure of roofing tile | Single layer tile | Single layer tile | Double layer tile | Double layer tile | Three layer tile(inner foaming) |

| Extruder model | SJZ80/156 | SJZ92/188 | SJZ80/156+SJ50 | SJZ92/188+SJ50 | SJZ51/105+SJZ65/132+SJZ51/105 |

| Width of tile | 710-1220mm | 710-1220mm | 710-1220mm | 710-1220mm | 710-1220mm |

Thicknedd of tile | 0.8-3.0mm | 0.8-3.0mm | 2.5-3.0mm | 2.5-3.0mm | 2.5-3.0mm |

| Extrusion capacity | 450-550kg/h | 600-700kg/h | 450-550kg/h | 600-700kg/h | 400-500kg/h |

The production line is mainly composed of feeding machine, twin screw extruder, mold, forming machine (glazed tile)/setting mold (wave tile), haul-off, cutting machine and stacking rack.After the material is plasticized by the extruder, it is extruded into sheets by the mold, and made into the shape of glazed tile or wavy tile by the forming machine or setting mold.The traction is controlled by the haul-off and cut by the cutting machine to the length we need.