Hotline:+86 17712582558

Email: sales@xhextrusion.com

Website: www.xhextrusion.com

Add: Huangqiao Industrial Park, Taixing City, Taizhou City, Jiangsu Province

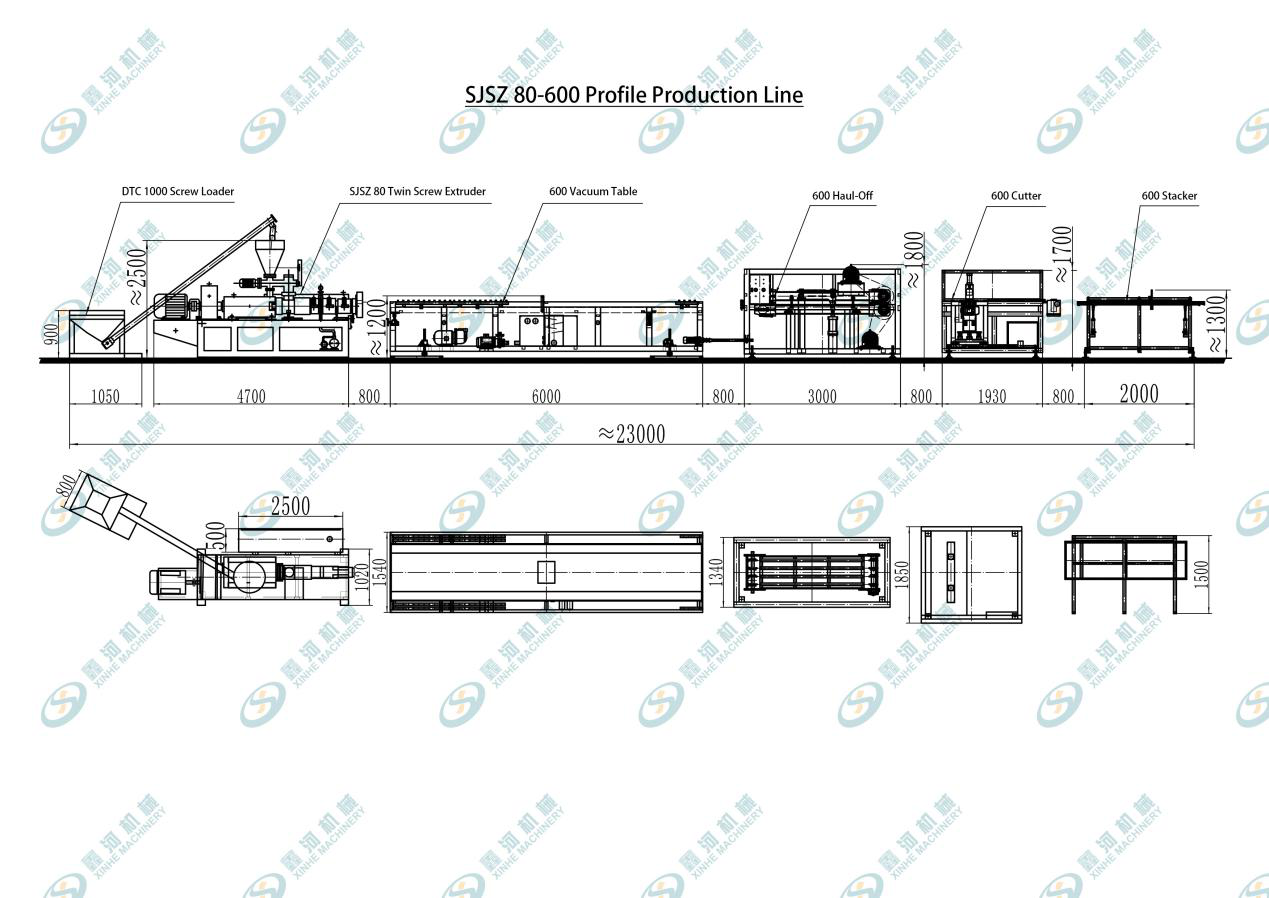

WPC door board, a combination of plastic and wood, is popular in many kinds of furniture. The composition of WPC board production line: screw loader, twin screw extruder, mold, vacuum table, haul off machine, cutter machine,stacker

| Model | YF600 | YF800 | YF1000 | YF1250 |

| Max.width(mm) | 600 | 800 | 1000 | 1250 |

| Extruder model | SJZ80/156 | SJZ80/156 | SJZ92/188 | SJZ92/188 |

Main motor power(kw) | 55 | 55 | 132 | 132 |

| Max.capacity(kg/h) | 280 | 280 | 600 | 600 |

PVC door board production line is mainly used to produce PVC door, PVC wall panel . The surface of PVC door board can be treated by color printing and coated with glossy oil, or by transfer printing, or by lamination, which can make marble, wooden design on the surface of products.

The working process of PVC door board machine:

Raw material → twin screw extruder → vacuum table → haul-off → cutting machine → stacker

Twin Screw ExtruderElectric control cabinet: the main inverter and feeding frequency converter Motor、pump: main motor 75KW Feeder motor 1.5KW Capacity:300-400kg/h Temperature control display meter:Omron Major electrical components:Schneider Extruder speed control method:ABB |  |

| Vacuum TableLength: 4-6Meters Table fore-and-aft Move: Adopt 1.5KW Gearbox Speed Reducer Motor Adjusting Distance equal to 800mm Table Adjusting: Up-and-down adjusting adopt worm reducer & screw adjusting |

Haul-offCompaction Mode: Adopt pneumatic gas cylinder Cut Motor Power: 0.75KW*1PC Speed control method:ABB Haul-off structure:Two caterpillar |  |

| CutterCutting action controller : PLC The impact method:pneumatic impact Cutter structure:Saw type Saw diameter:100mm Maximum cutting surface:700mm |