Hotline:+86 17712582558

Email: sales@xhextrusion.com

Website: www.xhextrusion.com

Add: Huangqiao Industrial Park, Taixing City, Taizhou City, Jiangsu Province

Widely used in automobile wiring harness, electrical threading, machine tool circuit, lamp circuit casing, air conditioning, washing machine water pipe and other fields

| Model | Pipe Range(mm) | Screw diameter(mm) | Motor Power(kw) | Molding Power(kw) | Rewinder Power(kw) | Output(m/min) |

| SJ45 | 9-32 | 45 | 11 | 1.5 | 1.5 | 3-12 |

| SJ65 | 20-50 | 65 | 15 | 4 | 3 | 1.5-6 |

SJ75 | 50-110 | 75 | 30 | 4 | 4 | 1.2-5 |

| SJ90 | 75-160 | 90 | 37 | 5.5 | 5.5 | 1-5 |

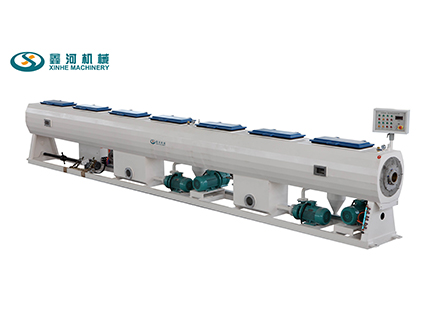

PE, PVC single wall bellows production line features:

PE, PVC single-wall bellows production line, through gear transmission module, template string water cooling, products air cooling, so that the production of bellows forming speed, corrugated shape uniform, consistent seams, smooth inner and outer wall, especially suitable for high-grade car wire harnesses. Single-wall corrugated pipe mainly uses PVC, PP, PE as raw material to produce small-caliber single-wall corrugated pipe. The pipe is widely used in prestressed trace element bushing, wire and cable threading bushing, air conditioner drainpipe, washing machine suction drainpipe, vacuum cleaner pipe, ventilation pipe and so on. Through the corresponding mold forming a smooth inside and outside, uniform bellows products. This product is a new product developed by our r & D personnel. This product has excellent performance, fast production speed and beautiful appearance. The single-wall bellows production line can continuously produce PE, PP, Eva, PVC bellows and pa bellows. Plastic single wall bellows with high temperature resistance, corrosion resistance, wear resistance, high strength, good flexibility and other characteristics. Widely used in automobile wiring harness, electrical threading, machine tool circuit, lamp circuit casing, air conditioning, washing machine water pipe and other fields

The working process of PE/PVC Single-Wall Corrugated Pipe Production Line:

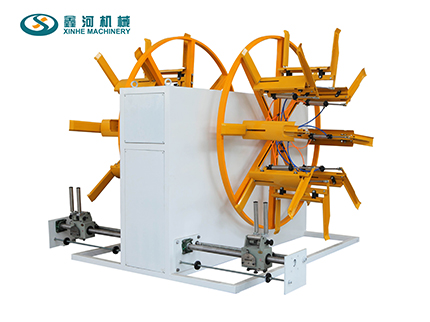

Raw material → extruder → vacuum table → haul-off → stacker

extruderScrew and Barrel: Screw and Barrel Material 38CrMoAlA, Nitriding, Surface Chrome plate, Nitriding Layer Thickness:0.5~0.7mm, Surface Rigidity:800~900HV. |  |

| Vacuum Tank Calibration Tank Length: 6m, Adopt 3mm thickness stainless steel board, Adopt 0.75KW Gearbox Speed Reducer Motor, Adjusting |

Haul-off Haul-off Bracket Length 1200mm, Adopt Pneumatic gas cylinder, Adopt 1.5kw*2sets ABB Inverter, Belt 80mm*2500mm. |  |

| twin screw extruderElectric control cabinet: the main inverter and feeding frequency converter Motor、pump: main motor 75KW,feeder motor 1.5KW Capacity:300-400kg/h |